LogistiQ conveyors are built to order based on our customer’s specifications. This approach allows us to provide equipment that is exactly as needed with short lead times. Leading the conveyor industry in built-to-order equipment, LogistiQ’s wide range of sizes and options allow us to offer as our standard product what our competitors would consider special equipment. Our material handling equipment is divided into the following product classes: Gravity Conveyors, Power Conveyors and Chutes.

Non-powered roller conveyors or Gravity Conveyors are the most economical and common method of conveying unit loads. These conveyors are typically mounted on a slight decline angle, therefore using gravity to assist product movement, especially for long distances. They can also be used in applications where the conveyor is level and operators can push the product along to its final destination, allowing for multiple workstations, if needed.

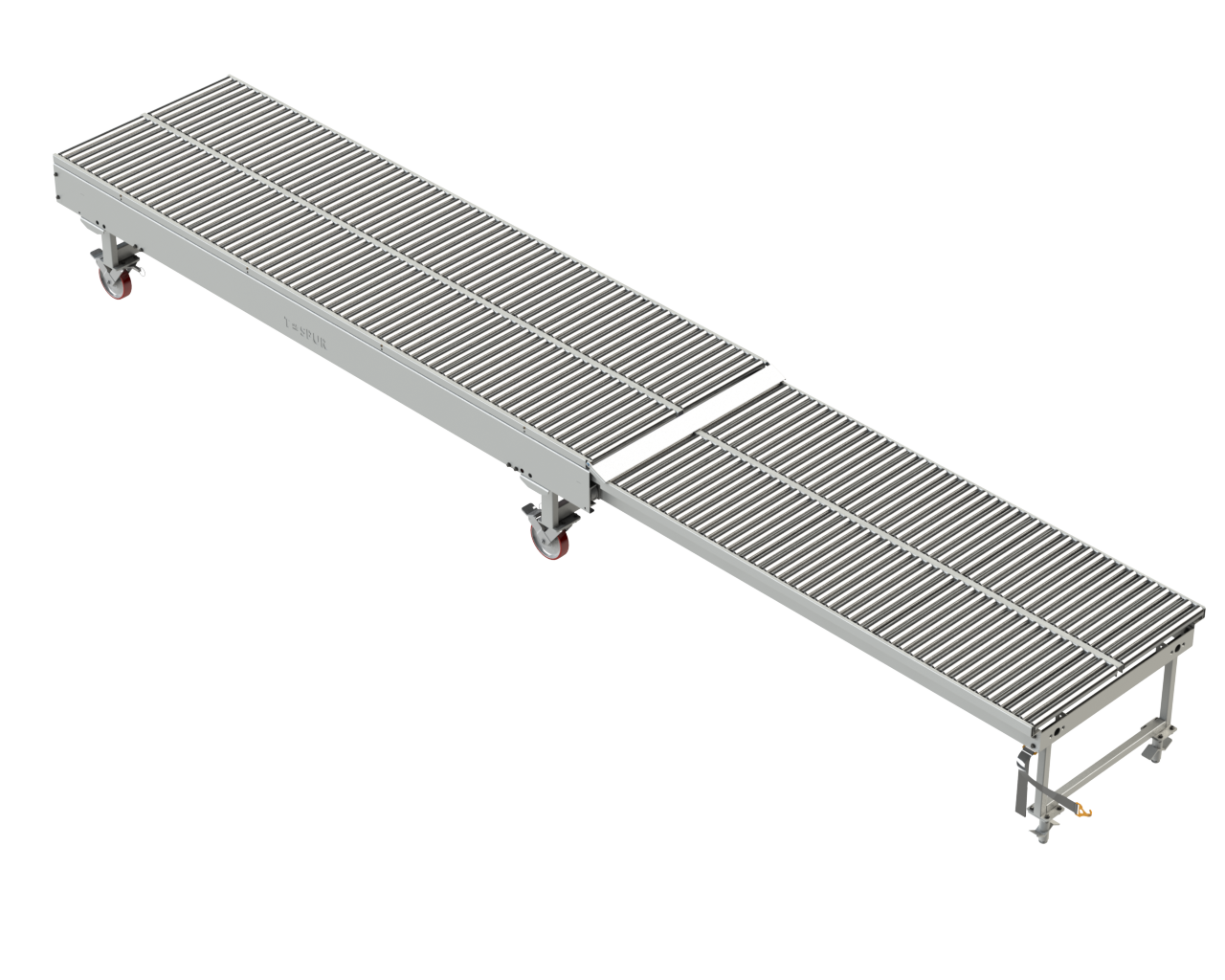

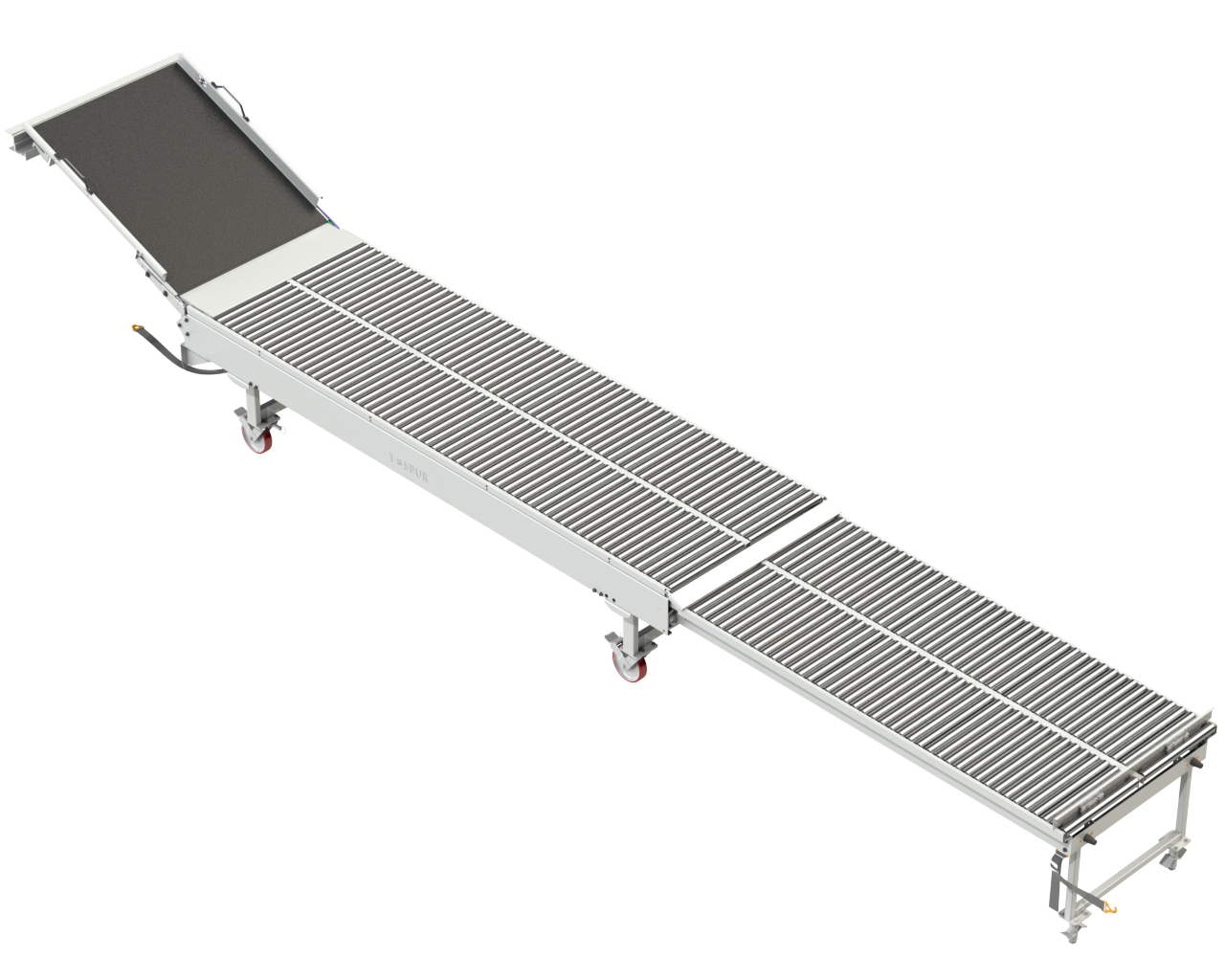

Portable T-Sort Roller Conveyor With & Without Chutes, Up To 60 Ft Long

Length, collapsed: 144”

Length, extended: 240”

With pivoting chute: 288.25”

Roller Centers: 2.25”

- Manual Sort Operations

- Loading & unloading Transport Vehicles D

- Available in (3) 20ft extendable mating sections

- 8” Offset Heavy Duty Swivel locking casters allow for easy maneuvering

- Torsion spring loaded pivoting chute

- Dual Lane 1.9 12g rollers on 2.25 centers

- Easy in & out extension

- Elevation: 33” +/- 3”

- Heavy-duty Leg supports

- Heavy-duty swivel caster with wheel lock on discharge end only

- Self-tracking extension and retraction

- Mechanical: 12 Months

- Technical Support

- Installation & Setup

- Service Maintenance

- Application Support

- Hardware Support

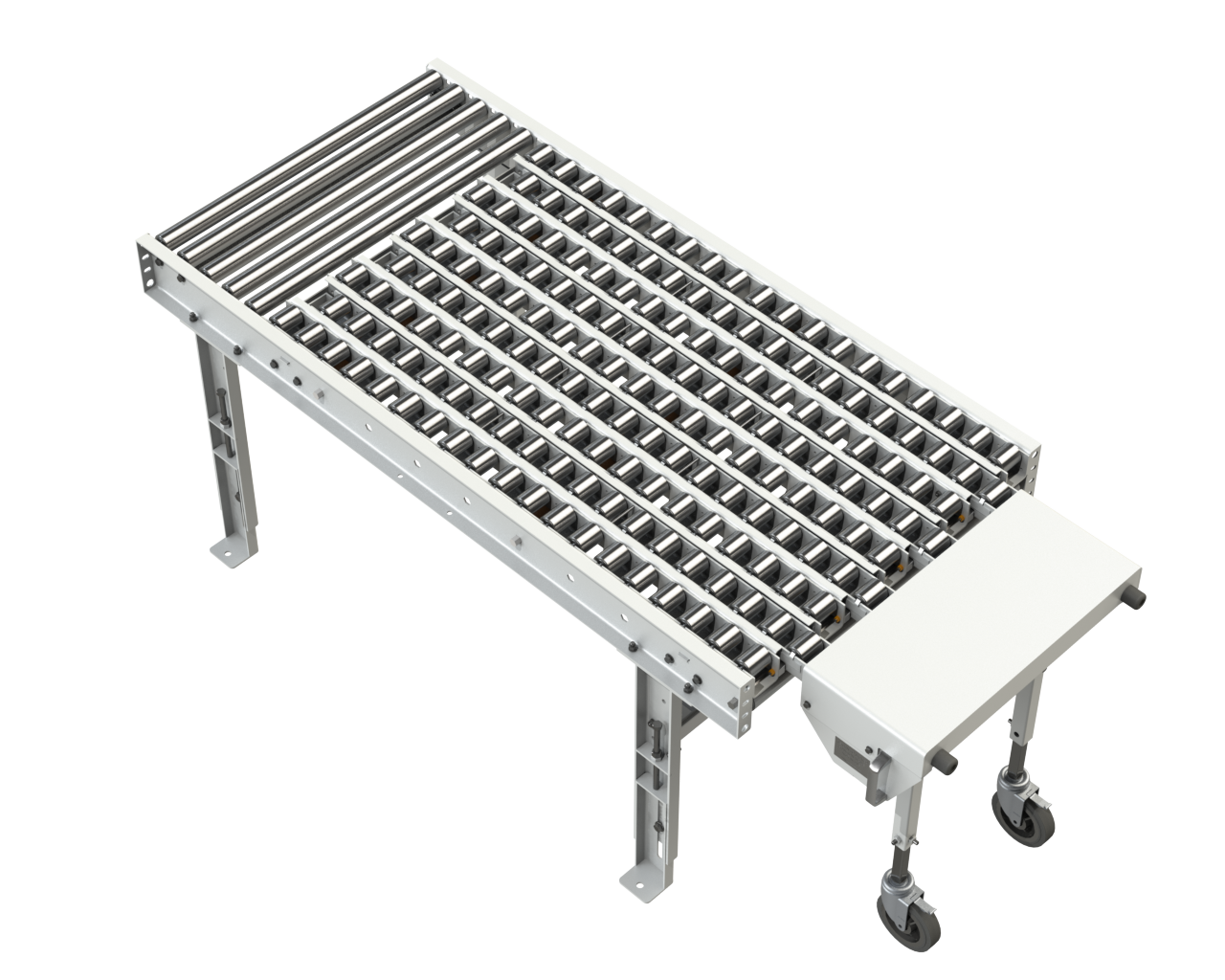

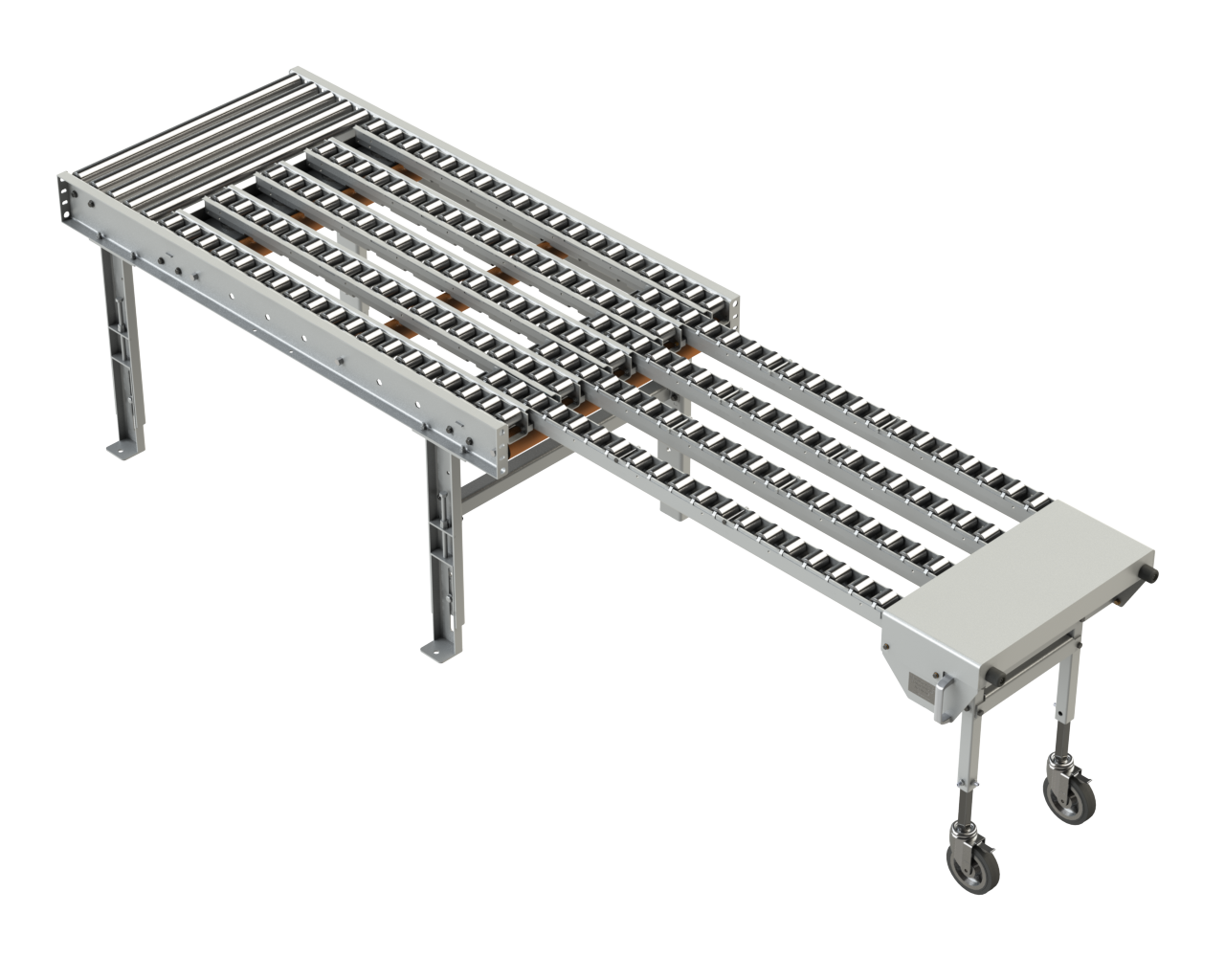

Finger Bridge Multi-Lane Extendable Gravity Conveyor

Length, collapsed: 87.5”

Length, extended: 133.5”

OR

Length, collapsed: 99.5”

Length, extended: 159.5”

Roller Centers: 3”

- Dock Doors

- Aisle Ways

- Egress in lieu of cross-over/stairways

- Large package handling

- Extendable Conveyor that maintains same surface elevation

- Allows for Easy Egress to aisle ways with extendable fingers

- Due to construction, provides easy maneuverability for all package sizes

- Multi Lane Gravity Roller Conveyor; 1.9 12g rollers on 2.25 centers

- Swivel lock casters allow for easy extending

- Heavy Duty impact pan on the end of extending fingers to protect the conveyor for robust handling applications.

- Elevation: 33” +/- 3”

- Roller Centers: 3”

- Rollers: Standard galvanized roller options

- 1.90” diameter, 12 ga. wall tube with 7/16” hex cold rolled steel axles, spring retained

- 2.5” diameter, 11 ga. wall tube with 11/16” hex cold rolled steel axles, spring retained

- Standard bearings are Semi-precision

- Heavy-duty Leg supports

- Heavy-duty swivel caster with wheel lock on discharge end only

- Self-tracking extension and retraction

- Mechanical: 12 Months

- Technical Support

- Installation & Setup

- Service Maintenance

- Application Support

- Hardware Support

Contact Us

Tell us your business challenges and needs and we'll get back to you ASAP!