The Powered Round Belt Drive Conveyor is a quiet and efficient live roller conveyor system. These systems are primarily suitable for lighter loads up to 75 pounds. Each roller is powered individually by a composite “O” ring or band with up to (16) rollers connected to a single 24v flat motor with integrated control cards. With the goal being simple to install, these conveyers are commonly used in zero pressure accumulation applications, integrated with pop-up transfers, curves or spurs.

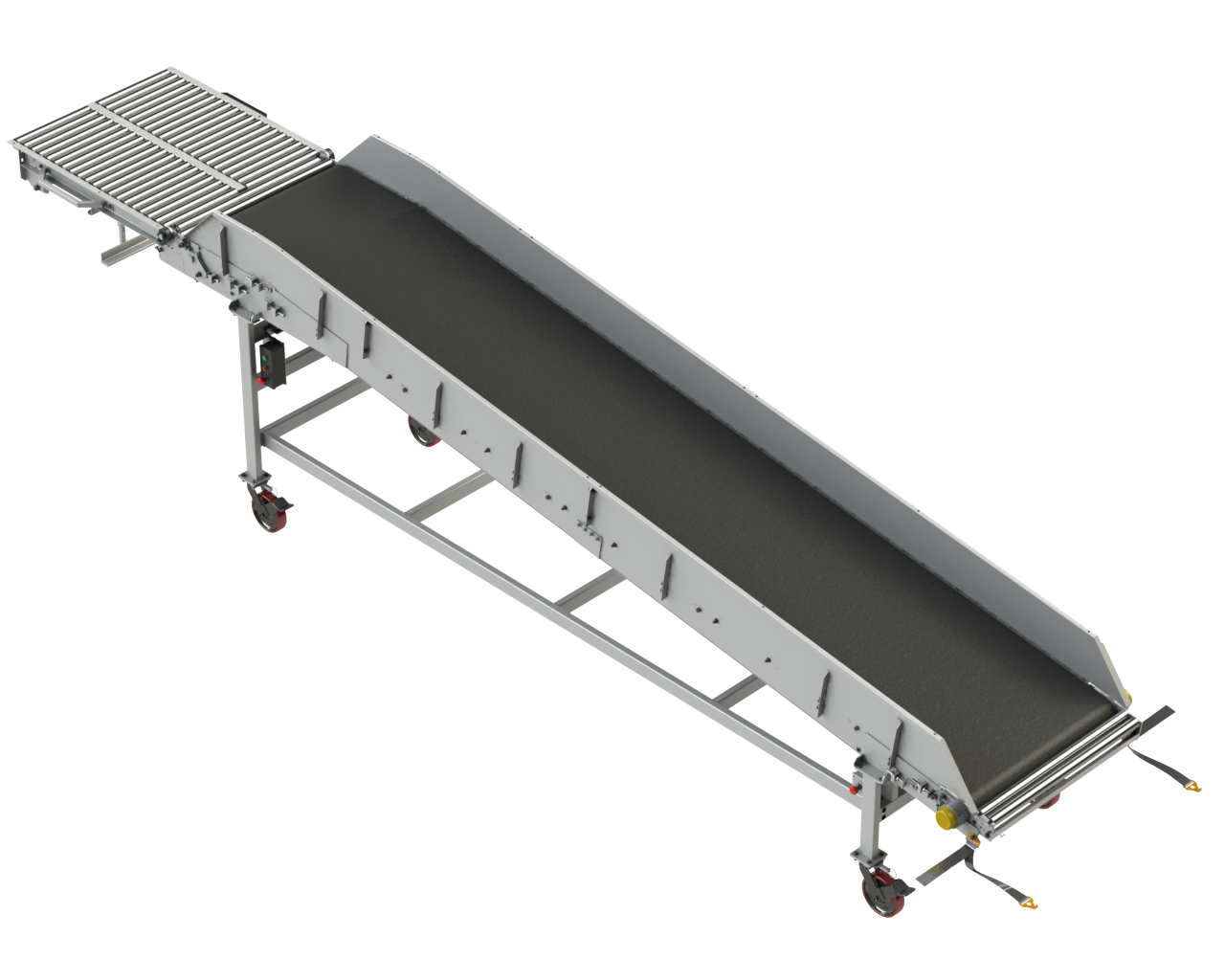

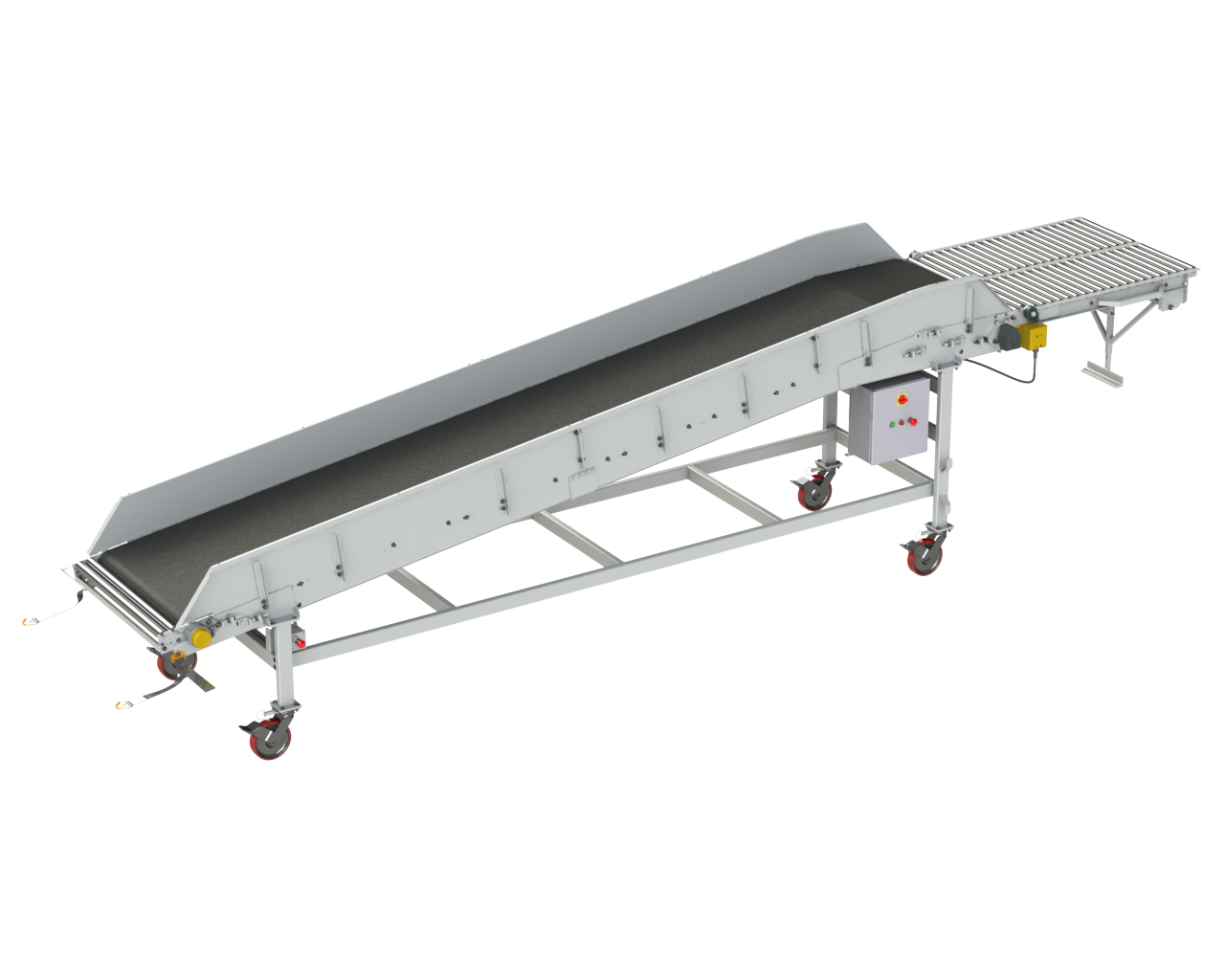

Portable T-Sort Powered Belt Conveyor

We developed a Portable T-Sort Powered Belt Conveyor with a mating portable

gravity section designed for mobility. This heavy duty unit is remarkably easy to

move, & offers a simple & effective means to handle difficult to convey products

in sorting, loading, or unloading applications. The UHMW lined Chute provides a

low friction surface at interface points, allowing operators to easily transfer these

challenging items on or off the adjoining surfaces. The unit is driven with a 2 HP

reversible motorized pulley that uses 115V, 1ph power. Its 20 ft long power cord

is supplied with a twist lock plug that stays put. This conveyor is a multi-use unit

that is easily deployed for whatever your special use needs might be.

• BELT WIDTH: 35.5”

• LENGTH WITHOUT CHUTE: 192”

• LENGTH WITH CHUTE: 288.25”

• ELEVATION IN-FEED: 31”

• ELEVATION DISCHARGE: 54”

• SPEED: 60 FPM, Variable Speed

• MOTOR: 1 HP, Reversible

• DRIVE: 1HP motorized pulley, reversible located within frame

• GUARD RAIL: Removable

• SUPPORTS: Heavy-duty Leg supports with swivel caster & wheel lock

• LENGTH WITHOUT CHUTE: 192”

• LENGTH WITH CHUTE: 288.25”

• ELEVATION IN-FEED: 31”

• ELEVATION DISCHARGE: 54”

• SPEED: 60 FPM, Variable Speed

• MOTOR: 1 HP, Reversible

• DRIVE: 1HP motorized pulley, reversible located within frame

• GUARD RAIL: Removable

• SUPPORTS: Heavy-duty Leg supports with swivel caster & wheel lock

• Reversible Incline/Decline

• Lift Gate for Egress Access

• 115 V Single Phase Power

• Variable Speed

• Removable Side Rails for Oversized Package

• Optional Gravity Roller In-Feed Conveyor

• Plug & Play Electrical Connections

• 8” Offset Heavy Duty Swivel Locking Casters

Allow for Easy Maneuvering

• Lift Gate for Egress Access

• 115 V Single Phase Power

• Variable Speed

• Removable Side Rails for Oversized Package

• Optional Gravity Roller In-Feed Conveyor

• Plug & Play Electrical Connections

• 8” Offset Heavy Duty Swivel Locking Casters

Allow for Easy Maneuvering

• Manual Sort Operations

• Loading & Unloading Transport Vehicles

• Loading & Unloading Transport Vehicles

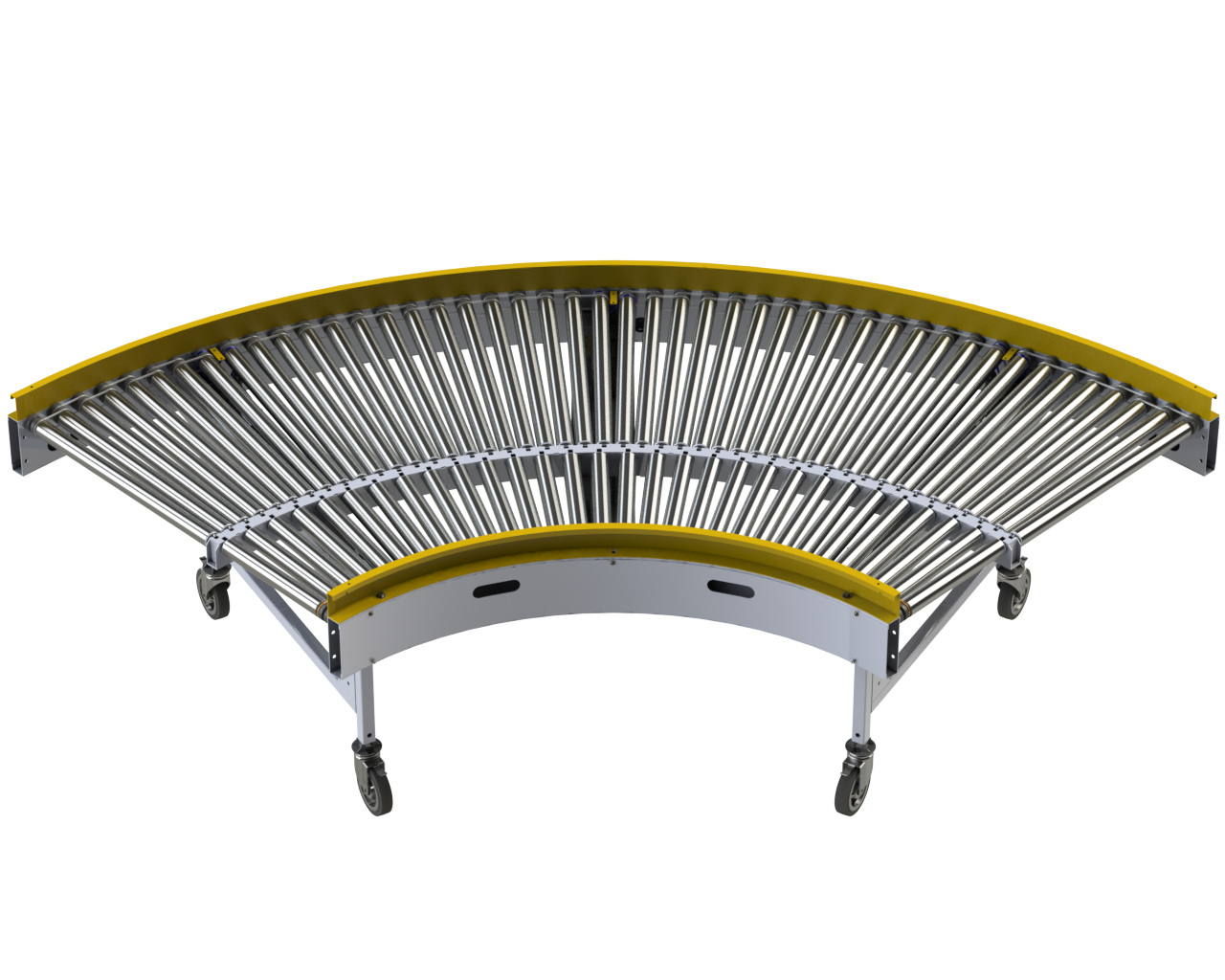

Modular Portable Roller Conveyor - MPRC

Keeping up with the continually changing & ever-growing retail, e-commerce and

distribution industries can be a daunting task as you strive to stay ahead of the pack.

The traditional fixed positioned conveying systems are designed to carry out a

single process, limiting flexibility required for ever-changing demand. We developed

an innovative modular conveyor system that is configurable, portable, quiet, durable,

& cost-effective. Our Modular Portable Roller Conveyor (MPRC) system can connect

in straight runs up to 80 feet with a single 110v power drop. The system can combine

with powered curves to maneuver around existing equipment or building structures.

Our configurable conveying system can provide you with the flexibility you need to

manage ever-changing markets.

CONVEYING WIDTH: 36” OR 48”

The effective conveying width is determined by package size, available floor space, & application specific needs

CONVEYING ELEVATION: 24” – 48”

Standard conveying elevation is 32”, but load & unload areas can be lower or higher as needed. Elevations higher & lower than this range can be achieved on a custom basis

LENGTH (STRAIGHT): 60” / 120”

The standard individual straight section is 120” long; these can be coupled together for runs of any length needed. Lengths other than the standard 60” & 120” are available on a custom basis but need to be divisible by the roller centers

DEGREE (CURVED): 30° / 45° / 60° / 90°

90° turns are standard on most systems, but 30°, 45°, & 60° turns are available as needed for special layout situations

The effective conveying width is determined by package size, available floor space, & application specific needs

Standard conveying elevation is 32”, but load & unload areas can be lower or higher as needed. Elevations higher & lower than this range can be achieved on a custom basis

The standard individual straight section is 120” long; these can be coupled together for runs of any length needed. Lengths other than the standard 60” & 120” are available on a custom basis but need to be divisible by the roller centers

90° turns are standard on most systems, but 30°, 45°, & 60° turns are available as needed for special layout situations

• Safe – No Guarding

• Portable

• Configurable/Re-Configurable

• 110v Single Phase Power Req.

• Reversible

• Variable Speed

• Close Roller Centers

• Fully assembled for Easy Installation

• Plug & Play

• Requires Minimal Spare Parts

• Smooth Operation

• Quiet

• Portable

• Configurable/Re-Configurable

• 110v Single Phase Power Req.

• Reversible

• Variable Speed

• Close Roller Centers

• Fully assembled for Easy Installation

• Plug & Play

• Requires Minimal Spare Parts

• Smooth Operation

• Quiet

• Transportation

• Sortation

• Merging

• Dock Delivery

• Zone Accumulation

• Creating Gaps

• Parcel Fulfillment

• Sortation

• Merging

• Dock Delivery

• Zone Accumulation

• Creating Gaps

• Parcel Fulfillment

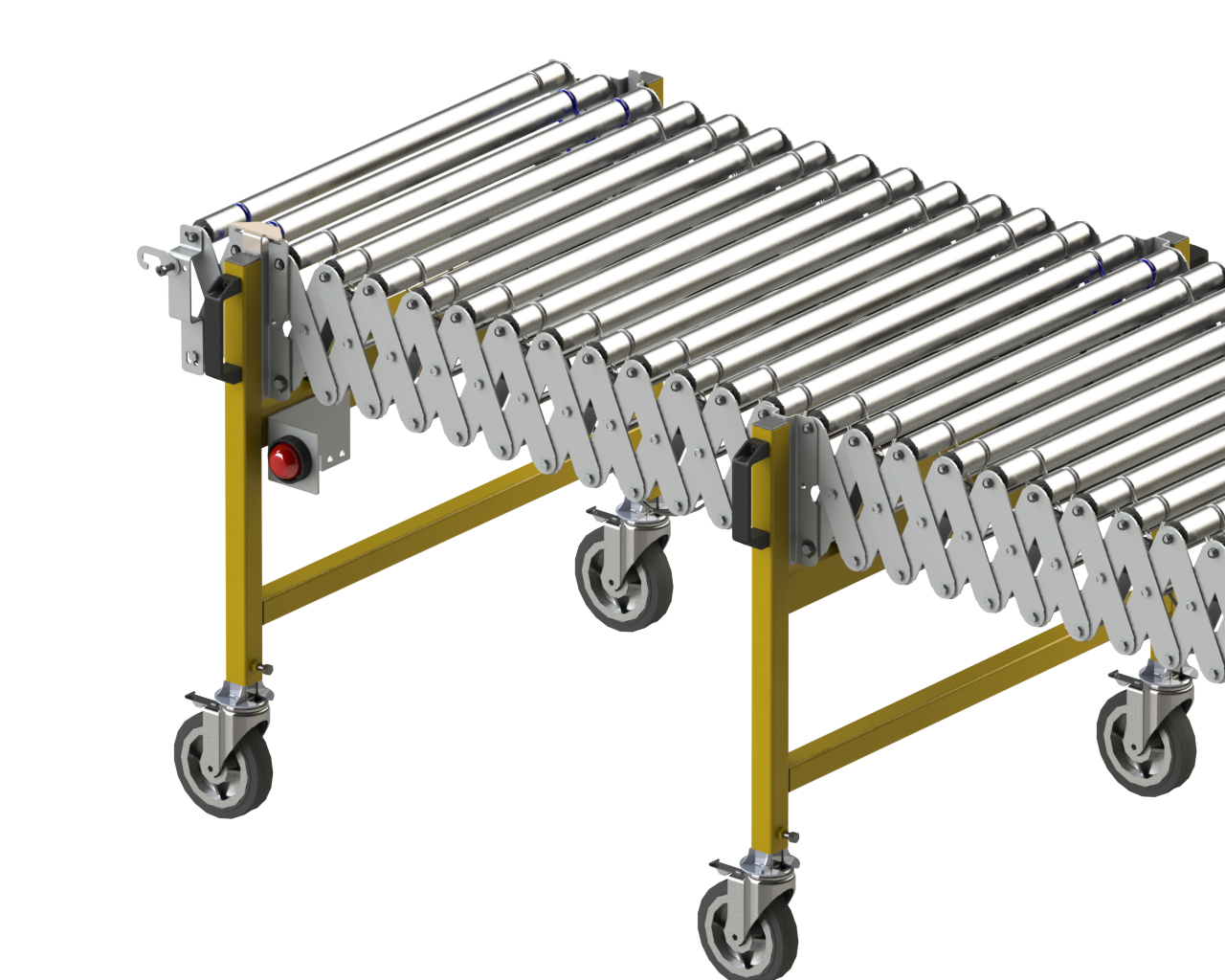

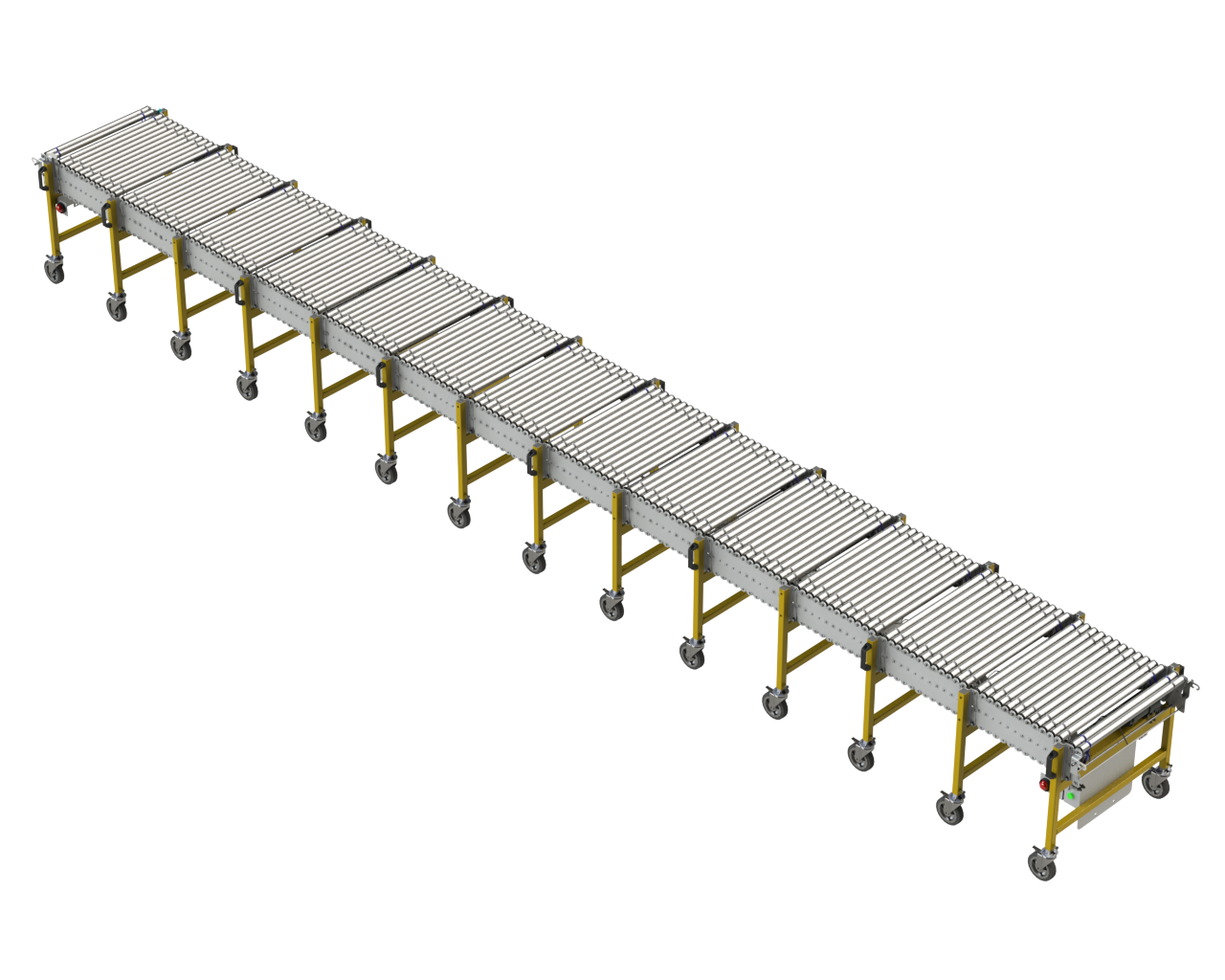

Flexible Portable Roller Conveyor - FLEX

Keeping up with the continually changing & ever-growing retail, e-commerce &

distribution industries can be a daunting task as you strive to stay ahead of the

pack. The traditional fixed positioned conveying systems are designed to carry

out a single process limiting flexibility required for ever-changing demand. We

developed an innovative flexible conveyor system that is expandable, portable,

quiet, durable, & cost-effective. Our Flexible Portable Roller Conveyor (FPRC)

system can connect in runs up to 80 feet with a single 110v power drop. This

versatile system can zig-zag to maneuver around existing equipment or building

structures, allowing the creation of a temporary conveyor line to meet everchanging

needs. To complement this system, we developed an innovative

powered assist drive to allow the operator to easily maneuver the conveyor line.

Our flexible conveying system can provide you with the solution you need to

manage ever-changing markets.

- WIDTH: 18” / 24” / 30”

Determined by package size, available conveying area & application-specific needs - EXTENDED LENGTH: 12’ to 80’

Determined by total length needed, including curvatures & obstructions - ELEVATION: 24” - 48” fixed height

- SPEED: 20-150 FPM

- ROLLER: 1.50” / 1.90”diameter

16 ga wall tube with 5/16” cold rolled steel axles, spring retained. Standard bearings are ABEC precision, grease packed - ROLLER CENTERS: 3” / 4” / 5” / 5 ¼”

- DRIVE: Located on support structure between frames & between supports for zone accumulation

- MOTOR: 90 VDC, up to (16) per power supply

- POWER: 120 Volt, single phase, 60 hertz

- FRAME: Standard finish is Zinc Plated Side Plate with supports powder-coated

- SUPPORT CENTERS: 6” / 8” casters

- WEIGHT CAPACITY: 100lbs per LFT

• Safe – No Guarding

• Portable

• Configurable

• 110v Single Phase Power Req.

• Reversible

• Variable speed

• Power Assist

• Fully Assembled for Easy Installation

• Plug & Play

• Requires Minimal Spare Parts

• Smooth Operation

• Quiet

• Portable

• Configurable

• 110v Single Phase Power Req.

• Reversible

• Variable speed

• Power Assist

• Fully Assembled for Easy Installation

• Plug & Play

• Requires Minimal Spare Parts

• Smooth Operation

• Quiet

• Transportation

• Sortation

• Merging

• Dock Delivery

• Zone Accumulation

• Gapping

• Splitting

• Parcel Fulfillment

• Sortation

• Merging

• Dock Delivery

• Zone Accumulation

• Gapping

• Splitting

• Parcel Fulfillment

Contact Us

Tell us your business challenges and needs and we'll get back to you ASAP!