E-commerce has transformed the way the world shops and how business is conducted. LogistiQ is committed to providing the expertise, service and equipment that powers this transformation to better serve these types of distribution businesses:

Last Mile Delivery

As the expectations of ecommerce shoppers continue to push the limits delivery speed, LogistiQ is here with provide material handling conveyance solutions that best facilitate the movement of goods. Rely on a LogistiQ partnership for support in your race to develop new technologies that enable you to increase parcel volume, expedite deliveries and delight eCommerce consumers — all while managing your costs.

Sort Center

Sorting, scanning, stacking packages on pallets and everything else that goes with getting your customer orders ready for delivery. Operating a sortation center is as fast paced as it gets, and your LogistiQ team is ready to hit the ground running when it comes time for designing, fabricating and installing precisely what you need in conveyor systems to maximize speed, efficiencies and customer satisfaction.

Micro-Fufillment

Need a macro conveyance strategy for your micro-fulfillment center? Your LogistiQ team understands that your business thrives on combining the speed of localized, in-store pick-up with the efficiency of a large, automated warehouse. Our 750,000 square foot, state-of-the-art manufacturing facility is equipped to deliver the largest of conveyance system solutions that enable you to shorten delivery time.

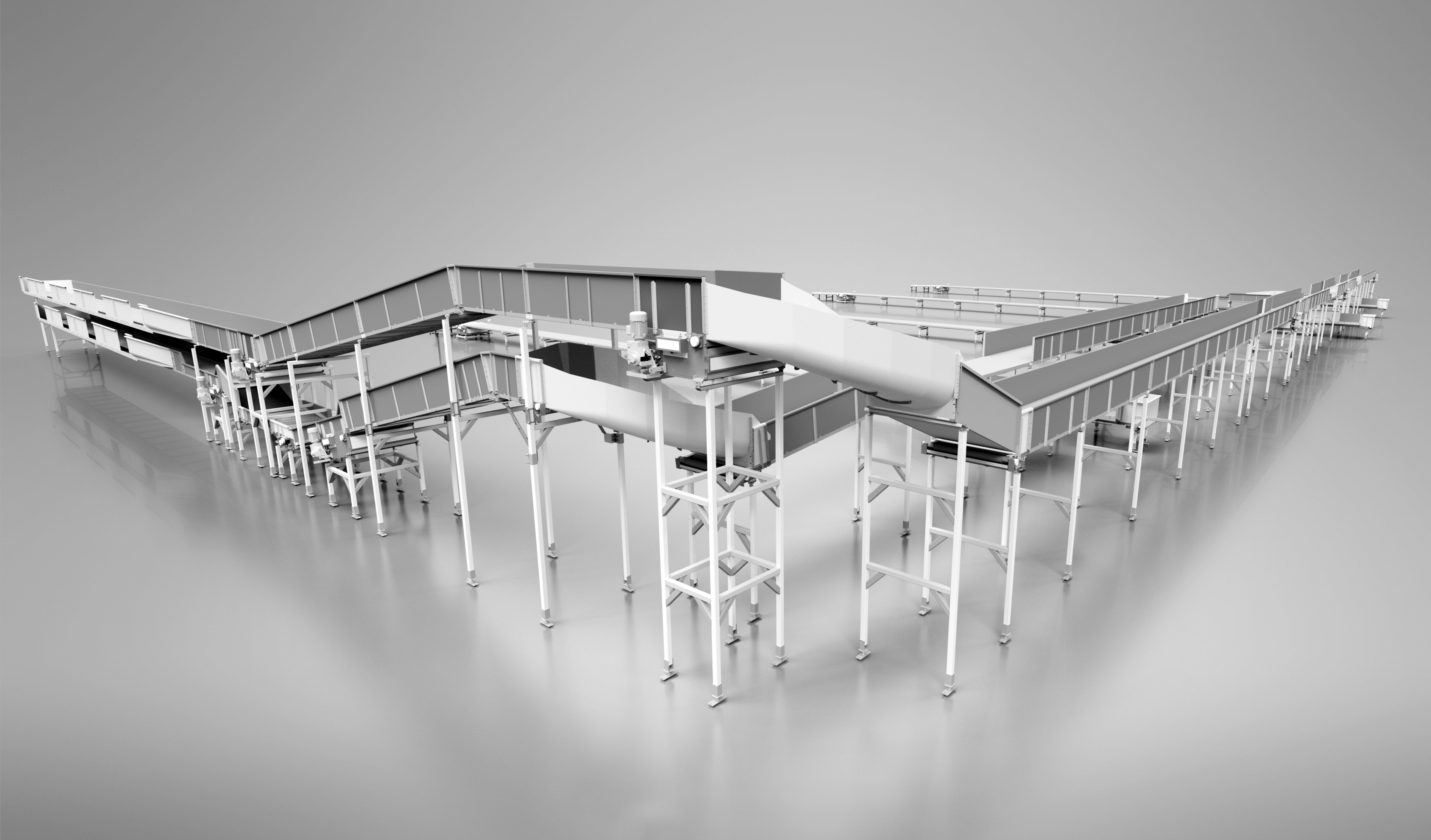

Parcel Belt Conveyor

• SPEED: 60-400fpm

• FRAME: 10-12g with Optional Impact Plates

• ELEVATION: Ground Elevated and Ceiling Supported

• GUARD RAIL: Standard: 10” 12” 24” Application Dependent

• MTBH: Box, Poly, RNC, Application Dependent

• SOUND: 80 db or under standard, Application Dependent

• Premium efficiency motors

• Smooth operation

• Reversible Incline/Decline

• Variable speed

• Conveying irregular packages

• Distribution & Fulfillment Centers

• Collection

• Sortation

• Inbound & Outbound

• Transportation

MATERIAL TO BE HANDLED

• Mailers

• Boxes

• RNC Bags

• Totes

• Original Containers

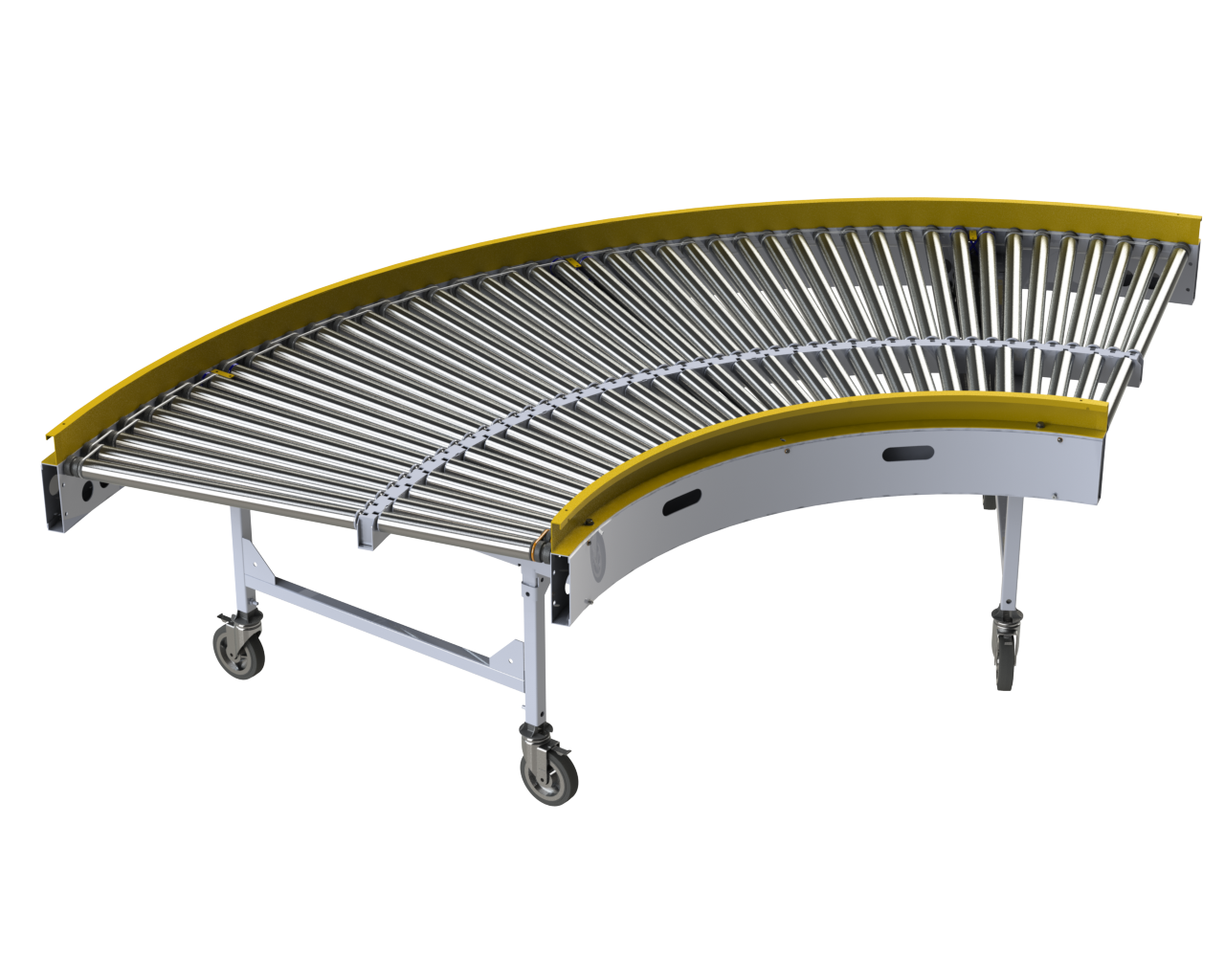

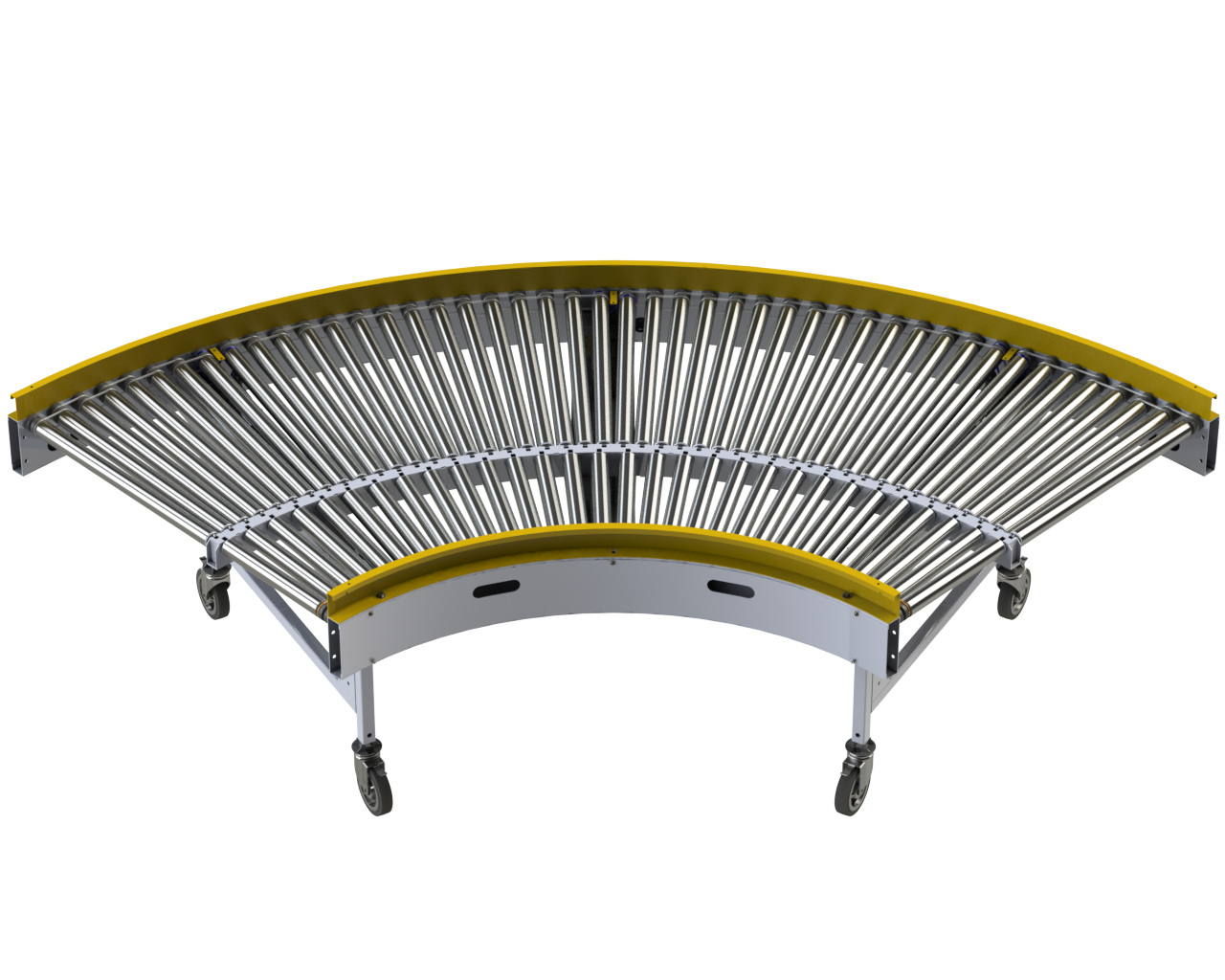

Modular Portable Roller Conveyor - MPRC

- CONVEYING WIDTH: 36” OR 48”

The effective conveying width is determined by package size, available floor space, & application specific needs - CONVEYING ELEVATION: 24” – 48”

Standard conveying elevation is 32”, but load & unload areas can be lower or higher as needed. Elevations higher & lower than this range can be achieved on a custom basis - LENGTH (STRAIGHT): 60” / 120”

The standard individual straight section is 120” long; these can be coupled together for runs of any length needed. Lengths other than the standard 60” & 120” are available on a custom basis but need to be divisible by the roller centers - DEGREE (CURVED): 30° / 45° / 60° / 90°

90° turns are standard on most systems, but 30°, 45°, & 60° turns are available as needed for special layout situations

• Portable

• Configurable/Re-Configurable

• 110v Single Phase Power Req.

• Reversible

• Variable Speed

• Close Roller Centers

• Fully assembled for Easy Installation

• Plug & Play

• Requires Minimal Spare Parts

• Smooth Operation

• Quiet

• Sortation

• Merging

• Dock Delivery

• Zone Accumulation

• Creating Gaps

• Parcel Fulfillment

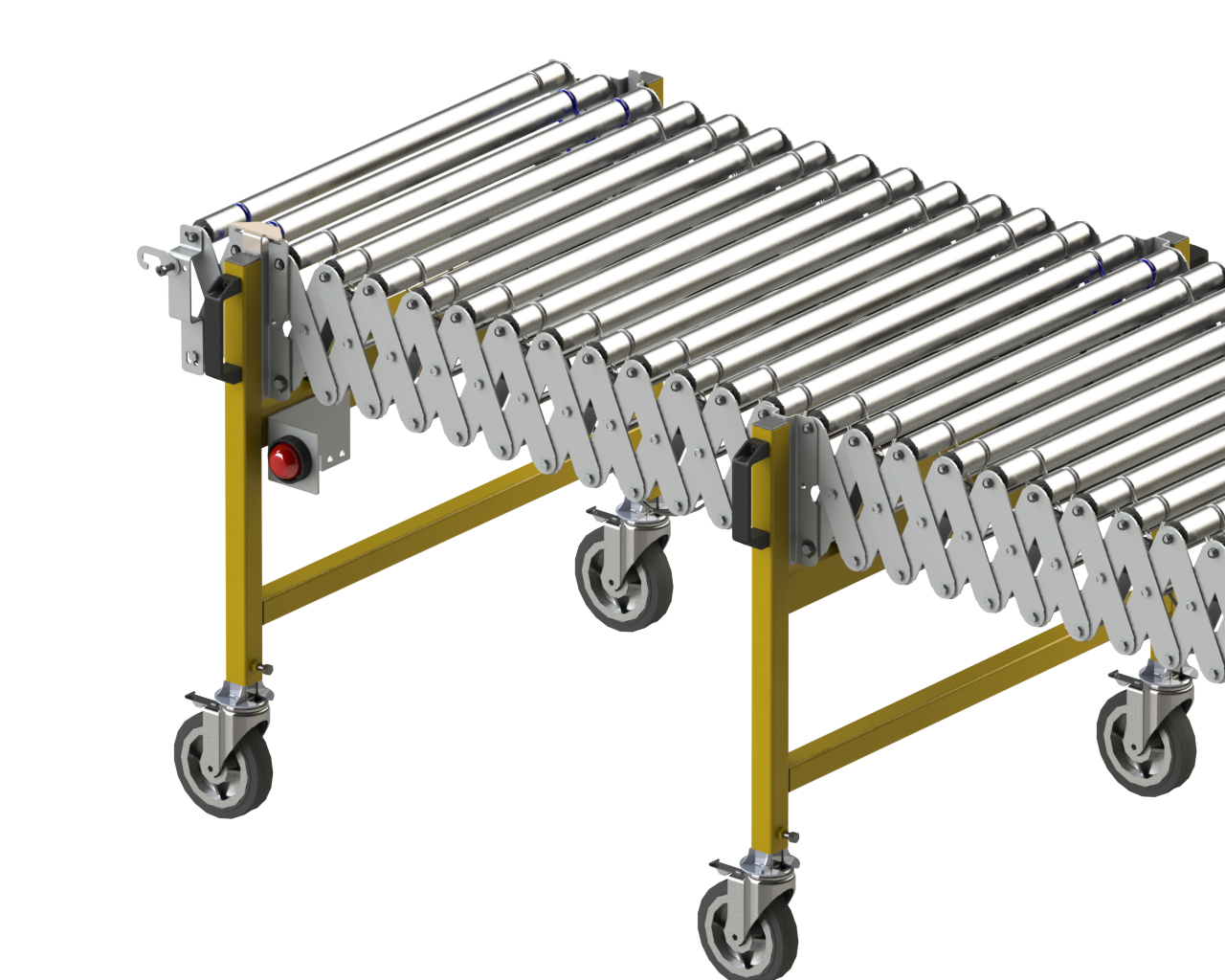

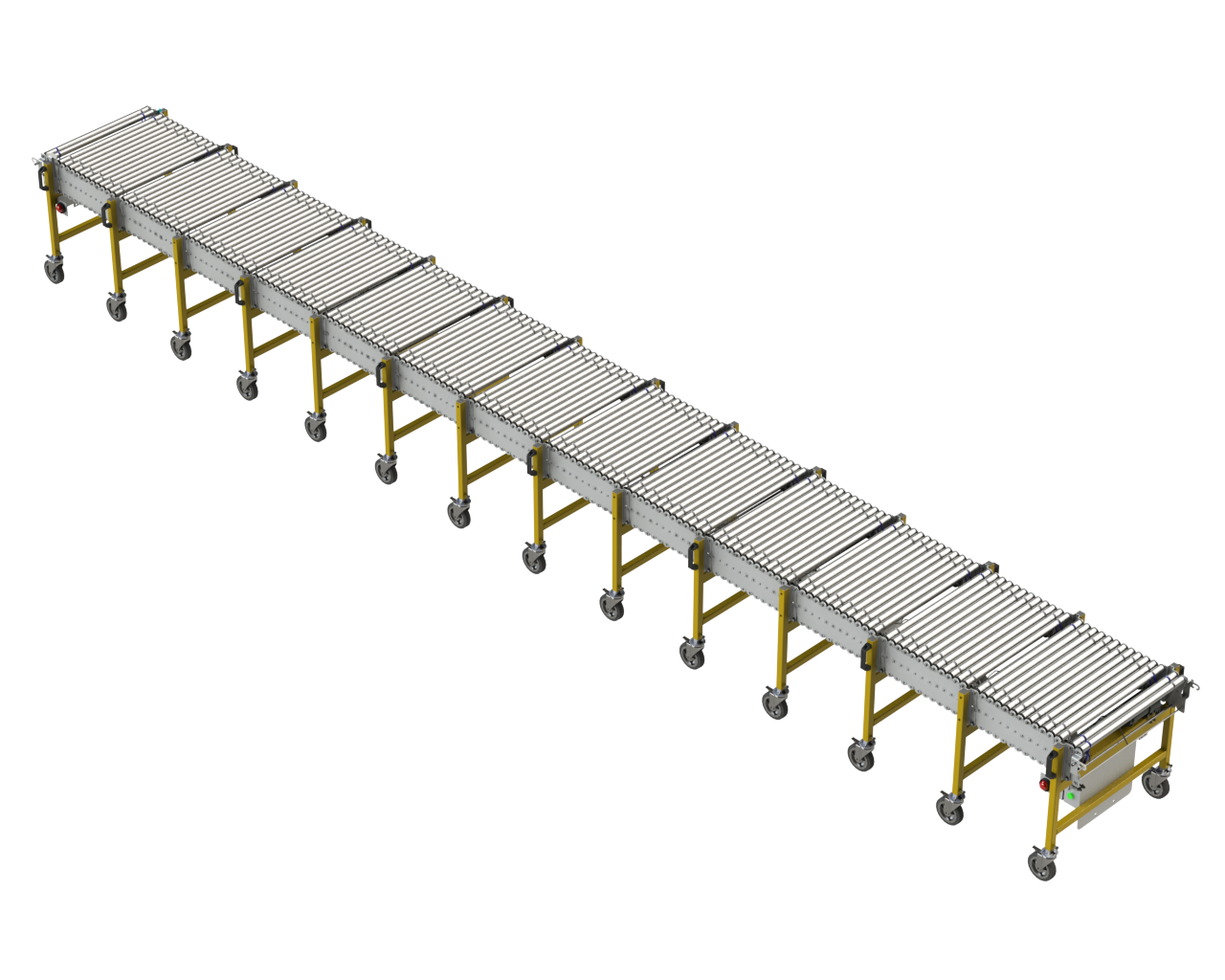

Flexible Portable Roller Conveyor - FLEX

- WIDTH: 18” / 24” / 30”

Determined by package size, available conveying area & application-specific needs - EXTENDED LENGTH: 12’ to 80’

Determined by total length needed, including curvatures & obstructions - ELEVATION: 24” - 48” fixed height

- SPEED: 20-150 FPM

- ROLLER: 1.50” / 1.90”diameter

16 ga wall tube with 5/16” cold rolled steel axles, spring retained. Standard bearings are ABEC precision, grease packed - ROLLER CENTERS: 3” / 4” / 5” / 5 ¼”

- DRIVE: Located on support structure between frames & between supports for zone accumulation

- MOTOR: 90 VDC, up to (16) per power supply

- POWER: 120 Volt, single phase, 60 hertz

- FRAME: Standard finish is Zinc Plated Side Plate with supports powder-coated

- SUPPORT CENTERS: 6” / 8” casters

- WEIGHT CAPACITY: 100lbs per LFT

• Portable

• Configurable

• 110v Single Phase Power Req.

• Reversible

• Variable speed

• Power Assist

• Fully Assembled for Easy Installation

• Plug & Play

• Requires Minimal Spare Parts

• Smooth Operation

• Quiet

• Sortation

• Merging

• Dock Delivery

• Zone Accumulation

• Gapping

• Splitting

• Parcel Fulfillment

Contact Us

Tell us your business challenges and needs and we'll get back to you ASAP!

Sales: 419-502-2728

LogistiQSales@lewcoinc.com

Service: 419-502-2779

LogistiQService@lewcoinc.com